Product Advantages

◆ PFAS-free material, compliant with EU regulations

◆ Low-temperature curing (<200°C), reducing thermal load during packaging processes and supporting carbon reduction initiatives

◆ Taper angle > 70°, enhancing stability in multi-layer structures for advanced packaging and RDL processes

◆ Low dielectric loss (Df < 0.01 @ 10 GHz), ensuring minimal signal loss for high-speed transmission and improved computing performance, suitable for VCSEL and other optical communication components

◆ High development resolution: film/via = 5 µm / 5 µm, 10 µm / 10 µm

◆ Excellent chemical resistance: effectively resists various organic solvents, alkaline solutions, and other corrosive chemicals

Product Specifications

Test Item | Unit | WLPT01-B | |

Exposure/Development /Resolution | Exposure Dose | mJ/cm2 | 350~550 |

| Developer | - | 2.38% TMAH | |

Resolution (Film/Via) | um | 10 / 5;10 / 10 | |

| Cure Conditions | Cure temperature | ℃ | 250~300 |

| Thermal Properties | Tg | ℃ | >300 |

| CTE | ppm/K | <55 | |

Practical Application Examples:

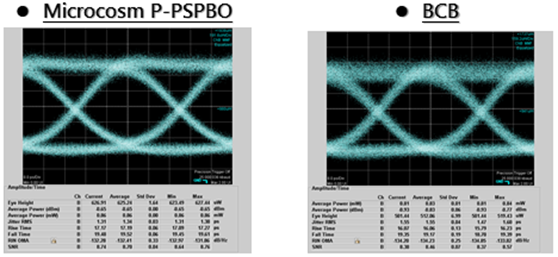

Microcosm P-PSPBO demonstrates lower RMS jitter

→ Eye quality of Microcosm P-PSPBO outperforms BCB

→ P-PSPBO provides better signal stability in high-speed transmission applications

For product-related information or detailed specifications, please contact us: sales@microcosm.com.tw